Robotics and AI: A New Investment Frontier

At the foundation layer of a regenerative economy are large-scale physical assets. Vast fields of solar panels, giant wind turbines, tractors on farms, cargo ships, food manufacturing factories, fire-breathing robots, plants purifying our air of CO2, and ocean-traversing vessels running on cleaner fuels.

Building and operating these assets requires (at least for the foreseeable future) a huge and highly-skilled labour force of contractors, operators, technicians, farmers, electricians, and more. These practitioners are critical enablers of our collective effort to transition to a more regenerative economy.

In recent years, a number of challenges have plagued the effort to decarbonise the economy. The most acute of these challenges is severe labour shortages caused by deteriorating demographics and years of underinvestment in apprenticeships and trades that will take many years to reverse.

In 2024, there are simply not enough skilled practitioners to do the work required to rapidly scale and deploy technologies to get to net-zero and beyond in a generation. U.S. unemployment is currently sitting at 4%, a full percentage below what economists generally consider to be “full employment” - or when the labour force is considered to be operating at maximum capacity.

The passage of the Inflation Reduction Act in the U.S. has further highlighted this skills and labour shortage, with industries such as solar requiring that its labour force will need to nearly triple in order to reach 2030 net-zero goals.

And yet, there is a huge wave of talent rising to address this challenge, harnessing their scientific, engineering and technological expertise to build software and hardware applications to mitigate climate change and create a regenerative economy. This talent wave is accompanied by additional mega-trends, such as the confluence of exploding market demand and breakthrough technological innovation, providing not only a scalable solution for labour shortages but also a once-in-a-generation investment opportunity. Never before has humanity experienced the convergence of such favourable trends along with rapid advances in critical-enabling technologies like we are witnessing now.

Software and AI-enabled Robotics will not only solve labour bottlenecks, they will also act as a force multiplier - unleashing step-changes in productivity and delivering products, services and new systems previously thought impossible by stacking together multiple breakthrough technologies by a single company.

We can highlight Aigen as a real-world example. Aigen combines world-leading power efficiency, AI, machine learning, and computer vision to create an autonomous vehicle that performs several on-farm tasks without consuming any inputs (it is fully powered by the sun and wind).

Robots equipped with superhuman strength, 360 degree-x-ray vision, and the ability to work continuously (they don’t get hot, tired or sick) and autonomously in harsh conditions will allow humans to focus on what we do best - thinking creatively to redesign systems for the better. The only limit is our own creativity and ingenuity.

Why now?

Robots are well-suited to perform tasks humans either can not (extremely harsh conditions, long hours with little downtime), or do not (extremely dull) want to do. These use cases naturally cover much of the work necessary for scaling climate technologies, including but not limited to solar panel installations, vegetation management, wildfire management, on-farm applications (weeding, picking, sorting, monitoring), assembling and disassembling batteries, and working in challenging, harsh, and dangerous environments like forests or the ocean.

We are currently in our third wave of robotics innovation, often labelled as Autonomous Mobile Robots, or “AMR”, which is enabled by the convergence of the following:

Artificial intelligence for robot autonomy: this will enable robots to have increased autonomy through large-language models and more rapid learning cycles. However, much of the recent boom in AI has been in GenAI, which focuses on image/text generation from prompts. We still need true multimodal learning models, as in-field robots work in unstructured, unpredictable environments.

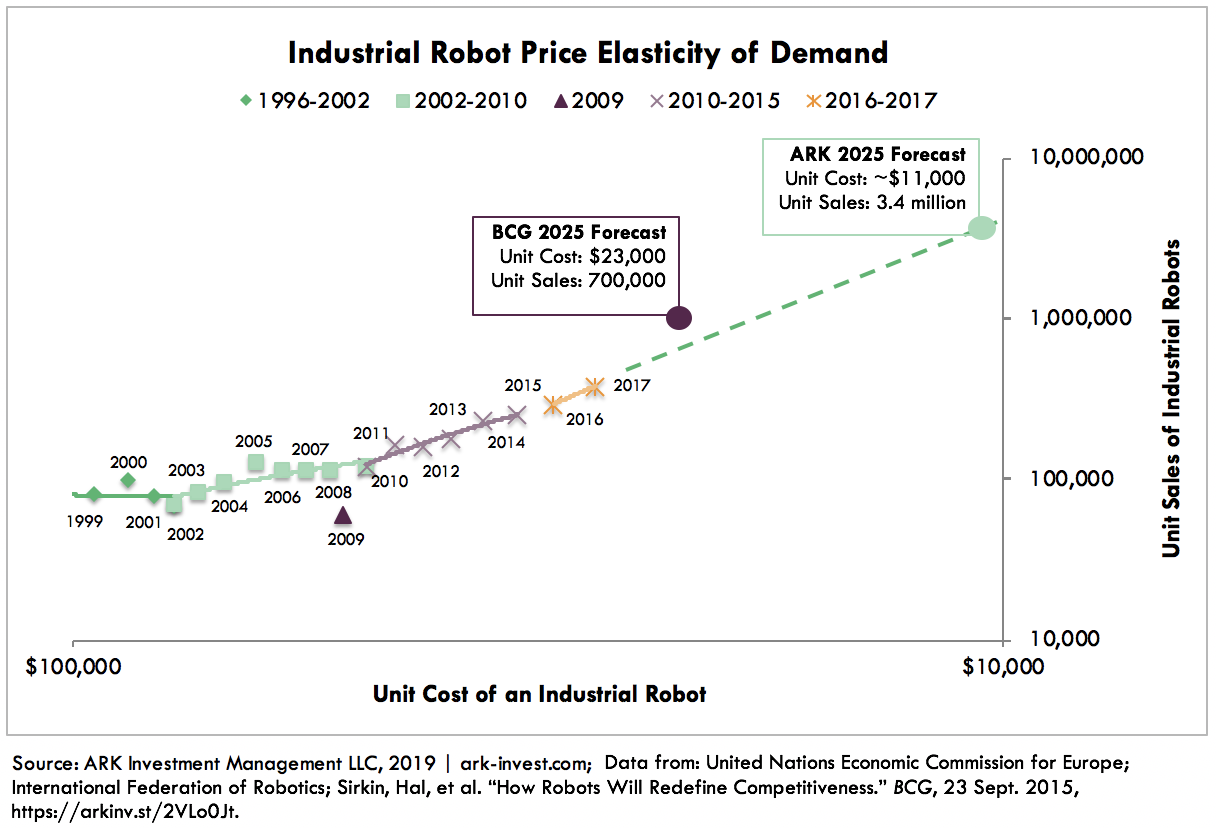

Better and cheaper components (e.g. cameras, sensors, motors, compute): these tools are the eyes and ears for robots, and improving their functionality while reducing costs will enable robots to work more effectively in harsher terrain and adapt when they face new obstacles and challenges, such as navigating crowded construction worksites. Learning curves, also known as Wright’s Law - where price per unit is a function of cumulative units produced - have been a strong driver of continuous cost reductions over time.

Edge computing and 5/6G connectivity: in order to rapidly process and transmit data, robots need to communicate continuously via 5/6G networks, low-orbit satellites and WAN/meshed networks. Accelerated deployments of these data networks will make smarter robots even more capable and cheaper.

Talent migration into robotics and artificial intelligence: numerous hardware startup alumni from companies such as SpaceX, Tesla, Rivian, Anduril et al. are starting companies of their own, often with even bolder and more audacious ambitions than the companies they have developed their skills. This explosion of radical ideas and sci-fi technology (especially in LA, South San Francisco and Boston) is further augmented by esteemed engineering schools like CalTech, MIT, Stanford, UC Berkeley, Oxford, Cambridge, University of Washington, etc.

These factors all lead to a forecast of industrial robots continuing to fall in price - hopefully making this technology soon ubiquitous and leading to a tipping point in adoption:

What we look for:

Given the systems-level innovation occurring and massive talent migration we continue to see, there have been countless robotics-enabled innovations. However, we believe robotics are best-suited for solutions which need rapid scale and deployment, often necessitating a slightly more mature industry where solutions already exist but inputs such as labour may not be sufficient.

We’ve been lucky to partner with several companies in this space, such as Aigen and BurnBot, and have been impressed by many more. BurnBot is scaling a robotics platform to clear dense brush and vegetation, perform controlled burns and improve ecosystem health while doing so.

Aigen makes AI and solar-powered mobile robots for farming which can analyse row crops, in addition to mechanically removing herbicide-resistant weeds. We’ve also had the pleasure of meeting many other companies working on problems from automating the assembly of battery packs, to finding ways of recycling building materials.

When speaking to these founding teams, we look for highly technical roboticists with strong engineering skills, often supplemented with AI/ML backgrounds in order to work on any technical challenges which may come their way. We also prefer slightly more mature markets and industries where innovation may be more welcome.

This maturity often comes with an elevated willingness to pay - such as in the case of wildfire prevention. Land managers who are aware of the costs of catastrophic wildfire understand the importance of deploying technologies at scale today, creating an opening to grow average customer values, contracts, and be early-movers.

In markets like California, BurnBot has gained incredible traction by augmenting the work of land managers and wildfire specialists with their controlled-burn robots which can operate in harsh, difficult-to-access terrain with a remote operator.

Robotics design is also crucial, with modularity and flexible design principles allowing for rapid iteration and faster scale along with lower upfront costs. This has a large impact on financing strategy, which can be a speed bump in the scaling of robotics and AI companies. Scaling hardware rapidly is rightfully a capital-intensive endeavour, so accessing capital such as equipment-financing and other low-cost debt will be necessary.

There are numerous other characteristics we like to see, such as: scalable manufacturing, strong unit economics with short payback periods, unique and differentiated IP moats, first-principles design thinking, quick iteration cycles, and vertically integrated business models to capture maximum value.

Conclusion

We are seeing an unprecedented confluence of technical innovation, talent migration, and strong demand for AI-enabled robots. There are so many unpredictable ways in which these technologies will transform our lives, but we are certain one of them will be in rapidly scaling solutions for a regenerative world.

As always, we welcome ambitious founders to change our minds about what is possible when we integrate AI, software, robotics, computer vision, clean energy, and battery storage. We’re certain that there are myriad applications that are currently being envisioned, and many more that are yet to even enter our imagination. This is just the start of a multi-decade transformation riding upon unstoppable tailwinds in the direction of building a regenerative economy for all. ReGen would be honoured to partner with you on your mission.